eurolaser: Speed and Precision through Customised Systems

- Publicado el 05 de Septiembre de 2018

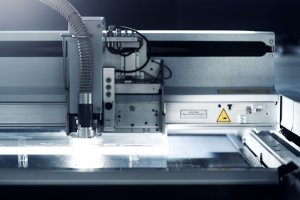

eurolaser CO2 laser systems are ideally suited for cutting and engraving extruded or cast acrylics, films and other plastics. Non-contact laser cutting is fast and precise. It instantly produces clear, smooth edges, without chips and post-processing. No product adhesion when machining adhesive films.

Polycarbonate, polyester, PET, composite or other types of plastic sheet, fabric or film need not be secured. Suitable table solutions ensure the optimal position of the materials. Processors benefit from laser certification by eurolaser, which is commissioned by well-known manufacturers of special materials.

Cost efficiency with the highest quality of results: No tool wear, consistently high cut quality and reduced material waste save costs. The parallel extension of the CO2 laser systems by additional mechanical tool heads allows using additional cutting, milling, ink-printing and labelling or an optical recognition system for precise cutting along a print contour.

eurolaser is one of the world's premium suppliers of modular laser systems of up to 3.20 meters in width and length. Depending on the processing material, laser sources of 60 to 600 watts are used.

The eurolaser table concepts are individually configured and are suitable for integration into industrial workflows 4.0. Additional time-saving automation components can be selected: from the shuttle table system (table changing system with parallel loading and unloading while using laser on the processing table) via remote operation (software-controlled division of the work surface for alternate operation) through to automatic placement by the Pick'n Place robot module - can be seen live on the FAKUMA (A4 / 4220).