Theegarten-Pactec certified as a climate-neutral company

- Publicado el 23 de Junio de 2023

Theegarten-Pactec has been CO2-neutral since the beginning of 2023. The Dresden-based company received the recognised "Climate neutral through compensation with climate protection certificates" seal from the sustainability company "Fokus Zukunft". For the certification, the environmental consultants recorded all greenhouse gas emissions directly related to their own value creation. The Dresden-based packaging specialist offsets this by acquiring climate protection certificates. The certification represents an important step for the company, which has long been actively involved in sustainability and environmental protection.

With the climate protection certificates, Theegarten-Pactec supports internationally recognised and controlled climate protection projects relating to wind energy, hydropower and biomass in various countries. The fact that companies can become climate neutral through financial participation in such important climate protection projects was formulated in the Kyoto Protocol adopted in 1997: Accordingly, greenhouse gases that are produced somewhere on Earth and are inevitable are to be saved elsewhere through climate protection projects. The logic behind it: For the climate, it is irrelevant where in the world the emissions are saved – the global total of greenhouse gases is what counts.

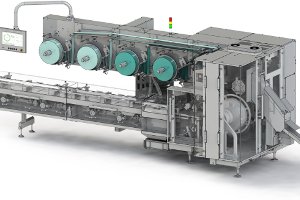

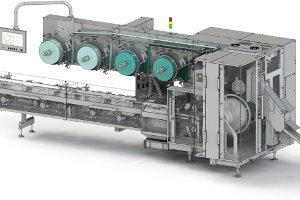

Theegarten-Pactec sees offsetting merely as an accompanying measure within a corporate climate strategy. Managing Director Markus Rustler already has plans for the future: "We initially adopted this approach in order for our company to become CO2-neutral from this year onwards. In the longer term, we will of course look at further savings opportunities. These could be achieved, for example, by building solar panels on our buildings or buying "green electricity". A further step will then involve the CO2-neutrality of our products. In addition, we use cast steel for the base housing of many of our machines. This is very energy-intensive, both in terms of production and in further processing. So, there is still room for improvement there, too. Because as a company, we are aware of our responsibility to contribute to a future worth living and we are absolutely committed to this."

Yet the figures on greenhouse gas emissions recorded so far do not look bad at all. Markus Rustler explains the calculations made by the environmental consultancy: "Fokus Zukunft certifies that we are already very well positioned as a machine builder with regard to our CO2 footprint. Especially with our new building of our headquarters in 2017 and the conversion of processes, we have already been able to reduce our emissions by 40 percent, even though we have increased our turnover and headcount in recent years." The main culprits are quickly identified. For example, business trips and electricity consumption make the biggest impact at Theegarten-Pactec. Markus Rustler explains further: "Unfortunately, we will not be able to do without electricity and business trips in the future either, as we have to install our machines on site at the customer's premises, for example. That is why we have looked at alternatives. The first step is to purchase high-quality CO2 certificates.

The emissions generated by Theegarten-Pactec's own business activities were recorded and accounted for by Fokus Zukunft in accordance with the guidelines of the globally accepted Greenhouse Gas Protocol Corporate Standard. Emission sources included in the calculation were heat consumption, fuel consumption, e.g. for company cars, gas leaks, e.g. refrigerants in production, consumption of electricity and district heating, business trips, employees' commutes, water consumption, waste generation, paper consumption and other emission sources.